Work clothing is often customised with a companies logo, the most popular methods being embroidery and print. At Aspire Work Clothing Ltd we supply many businesses in Poole and Dorset with embroidered and printed clothing and we are often asked ‘Which should I choose for workwear? Embroidery or print?’ The answer really depends on your requirements, it is not simply a case of one is better than the other.

Embroidery and print for workwear:

Most people are familiar with embroidery, the process where a design or logo is sewn onto fabric or a garment. Professionally, this is achieved using a computerised embroidery machine. It produces a very durable design or logo and looks very smart and professional.

There are a few methods for printing a logo. The most popular we offer are screen printing or vinyl printing. Screen printing is the process where ink is pushed through a fine mesh stencil (or screen) onto the garment below. Vinyl printing is where a logo or design is cut from pre-coloured vinyl material and then pressed using a heat press onto the garment. Both create a smart, crisp and clearly defined logo.

Read on to see whether embroidery or print would suit your requirements better …

Embroidery or Print – Consider your logo and artwork:

When deciding whether embroidery or print is most suitable, you should first consider your logo or artwork. Transferring your logo onto clothing needs some thought and sometimes small alterations.

Size of logo:

First think about the size of the logo needed. The most common positions for embroidery and print are on the left/right chest and large on the back.

A left/right chest logo can range from 60 – 95 mm, most often it is between 80-95 mm in width. This size of logo is generally suitable for both embroidery and print. Letters and symbols need to be a minimum height of 5 mm in order for them to read clearly once embroidered or printed. If your logo or design has smaller letters and symbols they may need to be enlarged (or removed) for a left/right chest logo. This most often applies to ‘strap line’ wording and trademark / copyright symbols.

A large back logo can be up to 280 mm in width. This size of logo is most suitable for print, where it will be flat, smooth and clear. Large prints on the back such as STAFF or your company’s web address work really well. On the other hand, large embroidered logos can sometimes stretch, pull or gather on the garment; therefore we generally do not recommend embroidering logos larger than 150 mm in width. Having said that we can and do embroider some large back logos but it really depends on the logo and the garment, so it would be best to contact us to discuss this further. We can be contacted via sales@aspireworkclothing.co.uk, our Contact Us web page or telephone 01202 695757.

Intricate logo designs and fonts:

Does your logo or artwork have any intricate design components or fonts? If so, print will be best for you as subtle font details and small intricate designs details are often lost with embroidery. Print creates a very crisp clean logo showing intricate elements of designs and fonts.

Colour gradients within the logo:

Gradients and shadows can be difficult to reproduce with embroidery as they require blending of thread colours to create the effect. As there are only so many variations of the thread colours, the gradient effect is often limited. Similarly, print is created from single colours and gradients cannot be achieved effectively.

Often customers are happy to remove the gradient and chose the dominant colour as this can create the best effect. However, if the gradient is central to your logo or image there are other print options we can consider so do get in touch to discuss this further. Contact us at sales@aspireworkclothin.co.uk, our Contact Us web page or telephone 01202 695757.

Individual Personalisation:

Individual names can be embroidered or vinyl printed. They are a popular choice. These can be initials or full names and are often positioned on the right chest of a polo shirt.

Embroidery or Print – type of garments required:

There is a vast and ever expanding selection of workwear that can be customised with your company’s logo and most can be both embroidered and printed but there are a few exceptions.

Embroidery Only:

There are a few fabrics which cannot be printed and can only be embroidered. These include knitted fabrics, such as jumpers and cardigans and certain polyester garments such as softshell jackets and fleeces. Other items including hats, need to embroidered as well.

Print Only:

Certain fabrics are best printed, including waterproof items (e.g. jackets, umbrellas) and very thin garments.

However, a note on waterproof jackets as these can be embroidered but it is important to remember the embroidery process will affect the waterproofing of the jacket over the logo. We often embroider jackets for our customers to create a consistent look or image but whether this is appropriate for your company will depend on the required use of the jacket.

Embroidery or Print – cost effectiveness of each

Cost is an important factor when deciding whether print or embroidery is most suitable.

The price for each is calculated differently. The cost of embroidery is based on the number of stitches it takes to create the logo. Whereas the cost of print is based on the number of colours within the logo as each colour requires either an additional screen or press. Put simply, if your design or logo has lots of colours then embroidery may be the most cost effective. If your design is very large and intricate and therefore would need a lot of stitches to create it, print may be the most cost effective.

There are other elements of cost to consider too.

Set Up:

A logo will need to be set up for both print and embroidery. There is a one off fee to either digitise the logo for embroidery or set up screens and the logo for print. If you decide to choose both embroidery and print, there will be two set up costs that are generated, one for each process. Many companies therefore minimise these costs by opting for one or the other.

Quantities needed:

The greater the quantities, the more cost effective the print or embroidery. If smaller runs are required (less than 50 items), embroidery and vinyl print are more cost effective.

Screen printing becomes the cost effective print of choice with runs of over 100 items. In fact we have a minimum of 15 items for screen printing because of the cost of set up of the screens.

When deciding whether embroidery or print is most suited also think about the quantities needed for re-orders. While you may need an initial large order, will you need to ‘top up’ with smaller quantities. This may mean embroidery or vinyl print are more appropriate.

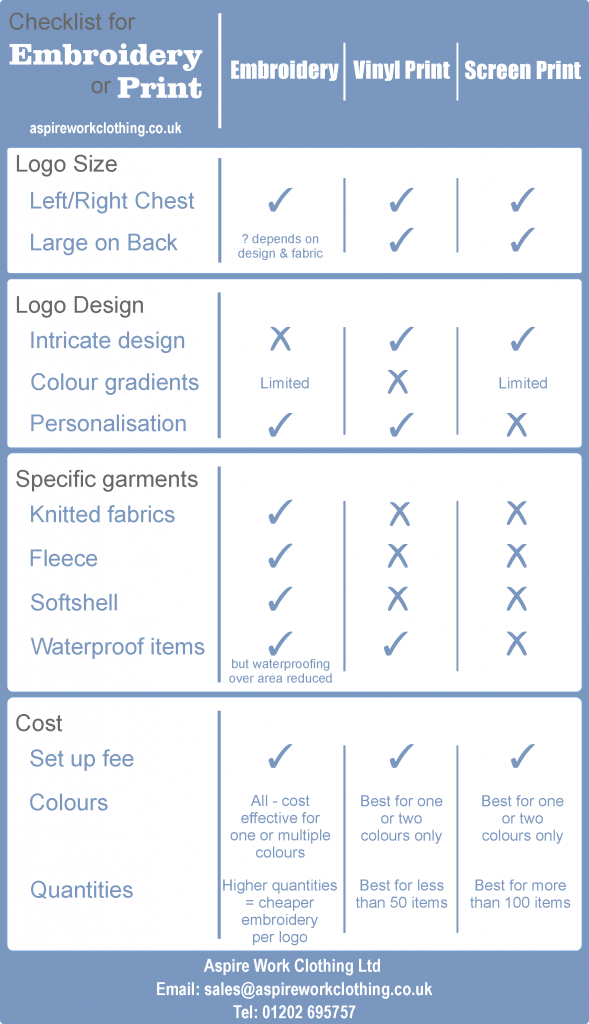

Embroidery or Print – A summary for you!:

Hopefully you will find the table below a useful summary …

We understand that deciding whether to have a garment embroidered or printed can be complex and we are more than happy to help. If you have any questions please get in touch, we at Aspire Work Clothing can be contacted via email, sales@aspireworkclothing.co.uk, via our Contact Us page or if you would prefer to talk to us, please phone 01202 695757. Don’t forget to attach an image of your logo or artwork!

We understand that deciding whether to have a garment embroidered or printed can be complex and we are more than happy to help. If you have any questions please get in touch, we at Aspire Work Clothing can be contacted via email, sales@aspireworkclothing.co.uk, via our Contact Us page or if you would prefer to talk to us, please phone 01202 695757. Don’t forget to attach an image of your logo or artwork!

Aspire Work Clothing Ltd